New energy PACK whole line solution provider

Configuration parameters and welding advantages of lithium battery laser welding machine

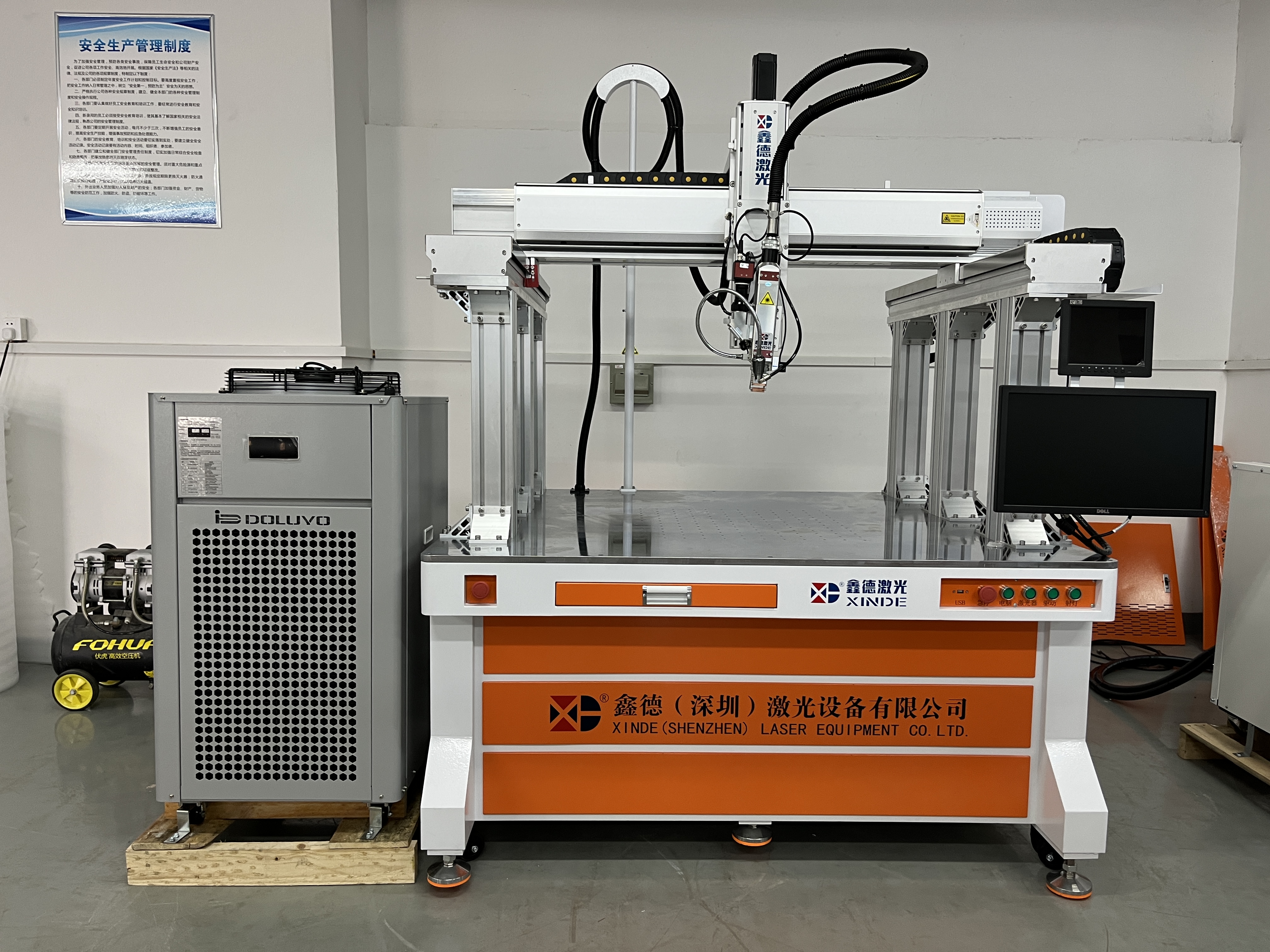

Xinde Laser is an automatic intelligent equipment technology enterprise focusing on new energy lithium battery laser welding. Its standard gantry laser welding machine equipment consists of:

1. Rack

2. Laser

3. Welding joint (single swing/double swing)

4. CCD monitor (10x magnification)

5. System Display (computer)

6. Water cooler

7. Servo motor

Its welding equipment has significant advantages:

1. Gantry frame movement structure, large surface stroke working welding range

2. The photoelectric conversion efficiency is high, and the beam quality is very good

3. Adjustable laser power, less power consumption, daily maintenance free

4. PC industrial computer, welding numerical control programming system, easy to learn

5. Support the addition of CCD visual positioning system, automatic focal length measurement system functions

Application Field:

Mainly used in new energy lithium batteries: Busbar welding, rotating stud welding, pole lug welding, nickel welding, confluence row welding, explosion-proof valve welding, shell sealing welding, liquid injection port welding, etc.

As we all know, the current lithium-ion battery in the rapid growth of energy density at the same time, the threshold for safety is also constantly raised. Good laser welding function can greatly reduce the failure rate of defective products. Poor quality lithium ion batteries will cause the risk of short circuit and thermal runaway.

1. Rack

2. Laser

3. Welding joint (single swing/double swing)

4. CCD monitor (10x magnification)

5. System Display (computer)

6. Water cooler

7. Servo motor

Its welding equipment has significant advantages:

1. Gantry frame movement structure, large surface stroke working welding range

2. The photoelectric conversion efficiency is high, and the beam quality is very good

3. Adjustable laser power, less power consumption, daily maintenance free

4. PC industrial computer, welding numerical control programming system, easy to learn

5. Support the addition of CCD visual positioning system, automatic focal length measurement system functions

Application Field:

Mainly used in new energy lithium batteries: Busbar welding, rotating stud welding, pole lug welding, nickel welding, confluence row welding, explosion-proof valve welding, shell sealing welding, liquid injection port welding, etc.

As we all know, the current lithium-ion battery in the rapid growth of energy density at the same time, the threshold for safety is also constantly raised. Good laser welding function can greatly reduce the failure rate of defective products. Poor quality lithium ion batteries will cause the risk of short circuit and thermal runaway.

Xinde Laser lithium battery welding equipment is not only fast welding speed, beautiful welding, under the premise of ensuring production, but also to ensure the quality and safety of the battery. Our company has perfect production equipment, cutting-edge technical personnel team, perfect after-sales service system, equipment products have been widely used in the lithium battery industry many well-known enterprises, superior quality has been widely recognized and supported by customers.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top