New energy PACK whole line solution provider

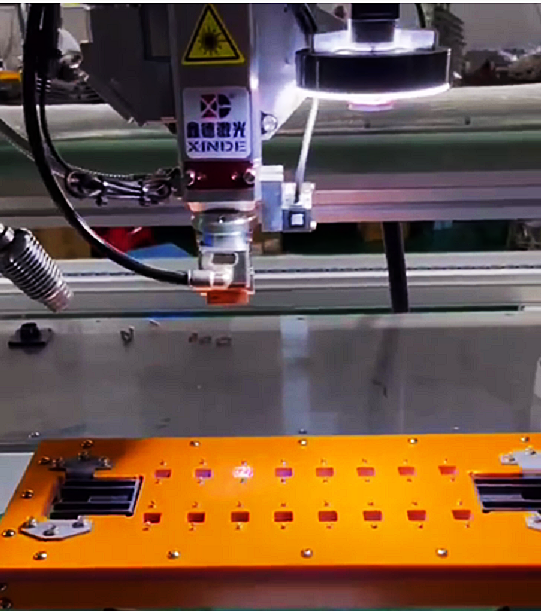

What factors are related to laser welding quality

In the actual laser welding machine, due to various reasons, there are a variety of problems. Therefore, in the production process, how to identify and solve these problems, is a very key link.

First, check the quality of welding, check the quality of parts is very important, there are usually visual inspection and destructive inspection, visual inspection is based on the rich work experience of the staff to judge the quality of welding products, and destructive inspection is a more scientific approach, we can tear the welding base material for inspection.

Two, after the detection, according to the phenomenon analysis of the problem, analysis of the cause of the fault, and then according to the laser welding machine parts for detection, to determine whether the laser welding machine focusing lens or parts loose.

Three, is to strengthen the management of laser welding machine, welding, to detect the pressure of the welding machine, to ensure the stability of the pressure of the welding machine, and to check the welding head regularly. Second, it is necessary to strengthen the control of current to prevent overheating caused by power, voltage and laser welding overload. Then the thickness and handling energy of the workpiece should be tested to avoid overheating.

First, check the quality of welding, check the quality of parts is very important, there are usually visual inspection and destructive inspection, visual inspection is based on the rich work experience of the staff to judge the quality of welding products, and destructive inspection is a more scientific approach, we can tear the welding base material for inspection.

Two, after the detection, according to the phenomenon analysis of the problem, analysis of the cause of the fault, and then according to the laser welding machine parts for detection, to determine whether the laser welding machine focusing lens or parts loose.

Three, is to strengthen the management of laser welding machine, welding, to detect the pressure of the welding machine, to ensure the stability of the pressure of the welding machine, and to check the welding head regularly. Second, it is necessary to strengthen the control of current to prevent overheating caused by power, voltage and laser welding overload. Then the thickness and handling energy of the workpiece should be tested to avoid overheating.

The selection of laser welding process mainly has three kinds: the selection of welding materials, the selection of laser welding equipment, the selection of processing table. Therefore, we can choose the right laser welder according to these three aspects, choose the right material to ensure the quality of welding.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top