New energy PACK whole line solution provider

Lithium battery PACK assembly line introduction

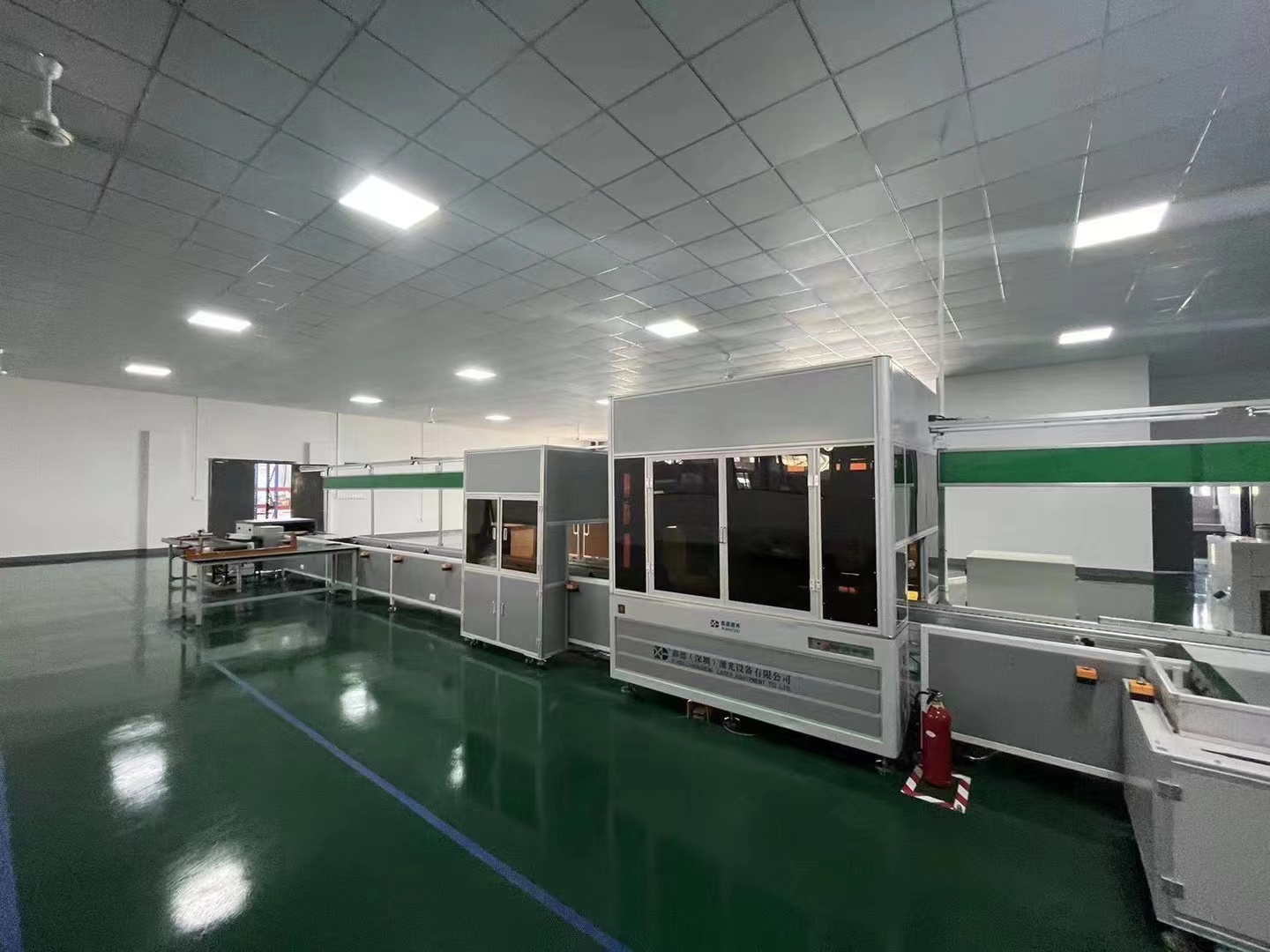

Xin De laser welding line:

Xin De laser welding line: the chain as a traction and carrier to transport materials, the chain can use ordinary power sleeve roller conveyor chain, can also use power belt line or double speed chain form of transmission;

Large conveying capacity, can bear large load; Accurate positioning is achieved by positioning and lifting.

Easy to achieve the accumulation and discharge transportation, can be used as an assembly line or as a material storage transportation;

Can work in a variety of harsh environment (high temperature, dust), reliable performance; Made of special aluminum profile, easy to install; Beautiful structure, low noise; Multi-function, high degree of automation.

Xindel laser welding pipeline can be added to the battery generated pack line, so that the welding process is no longer a separate process. This not only greatly reduces the labor cost, but also greatly improves the efficiency of welding.

The general process is as follows: the front end of the assembly line is linked to the battery pack to be welded at double speed. The welding process is controlled by PLC program and visual sensing system, which not only improves the efficiency of welding but also avoids the input of labor cost. After the welding is completed, it is transmitted to the next process by the conveyor chain.

(It can be combined with truss mechanism or boom to realize welding and complete the battery blanking process)

Xin De laser welding line: the chain as a traction and carrier to transport materials, the chain can use ordinary power sleeve roller conveyor chain, can also use power belt line or double speed chain form of transmission;

Large conveying capacity, can bear large load; Accurate positioning is achieved by positioning and lifting.

Easy to achieve the accumulation and discharge transportation, can be used as an assembly line or as a material storage transportation;

Can work in a variety of harsh environment (high temperature, dust), reliable performance; Made of special aluminum profile, easy to install; Beautiful structure, low noise; Multi-function, high degree of automation.

Xindel laser welding pipeline can be added to the battery generated pack line, so that the welding process is no longer a separate process. This not only greatly reduces the labor cost, but also greatly improves the efficiency of welding.

The general process is as follows: the front end of the assembly line is linked to the battery pack to be welded at double speed. The welding process is controlled by PLC program and visual sensing system, which not only improves the efficiency of welding but also avoids the input of labor cost. After the welding is completed, it is transmitted to the next process by the conveyor chain.

(It can be combined with truss mechanism or boom to realize welding and complete the battery blanking process)

The production line is made in accordance with the national standard, the distribution cabinet and the main body are installed in accordance with the strict requirements.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top