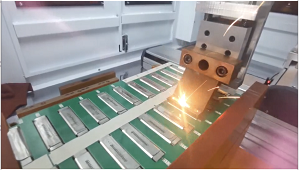

Xinde laser suggest you can learn more about the new welding equipment, laser welding machine it is a new type of welding equipment, mainly for the welding of thin-wall materials, precision parts, spot welding, butt welding, stack welding, sealing welding, deep width ratio is high, weld width is small, heat affected zone is small, small deformation, welding speed, smooth weld, beautiful, No processing or simple processing after welding, high weld quality, no porosity, accurate control, small focus spot, high positioning accuracy, easy to realize automation.

Advantages:

High speed, large depth and small deformation.

It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, a laser passes through an electromagnetic field and does not deflect the beam; The laser can be welded in vacuum, air and some gas environment, and can be welded through glass or transparent beam materials.

It can weld refractory materials such as titanium, quartz, etc., and can weld heterosexual materials with good results.

After laser focusing, the power density is high, in the welding of high power devices, the depth to width ratio can be up to 5:1, up to 10:1.

Micro welding is available. The laser beam can obtain a small spot after focusing, and can be accurately positioned, which can be used in the mass automatic production of micro and small workpiece welding.

Disadvantages:

The weldment assembly precision is required to be high, and the position of the beam on the workpiece should not be deviated significantly. This is because after laser focusing, the spot is small, the weld is narrow, and it is filled with metal materials. If the workpiece assembly accuracy or beam positioning accuracy can not meet the requirements, it is easy to cause welding defects.

The cost of laser and its related system is high and the one-time investment is large.

Laser welding is the radiation of high intensity laser beam to the metal surface, through the interaction between laser and metal, metal melting formed welding. Metal melting is only one of the physical phenomena in the interaction between laser and metal. Sometimes the light energy is not mainly converted into metal melting, but in other forms, such as vaporization, plasma formation, etc. However, in order to achieve good fusion welding, metal melting must be the main form of energy conversion. Therefore, it is necessary to understand the various physical phenomena produced by the interaction between laser and metal and the relationship between these physical phenomena and laser parameters, so that the laser energy is mostly converted into the energy of metal melting by controlling the laser parameters, so as to achieve the purpose of welding.

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top