New energy PACK whole line solution provider

There are four common types of laser welding

Battery explosion-proof valve welding: battery explosion-proof valve is a thin-walled valve body installed on the battery sealing plate, in the case of battery pressure greater than the specified, will make the valve body fracture, so as to prevent the battery explosion. Safety valve design is very delicate, this process requires very high laser welding technology. Before the use of continuous laser welding, the use of pulsed laser welding battery explosion-proof valve, the overlap and cover between solder joints and solder joints can achieve continuous welding, but its welding efficiency and sealing are relatively poor. Continuous laser welding technology is used to ensure the stability, efficiency and yield of welding products.

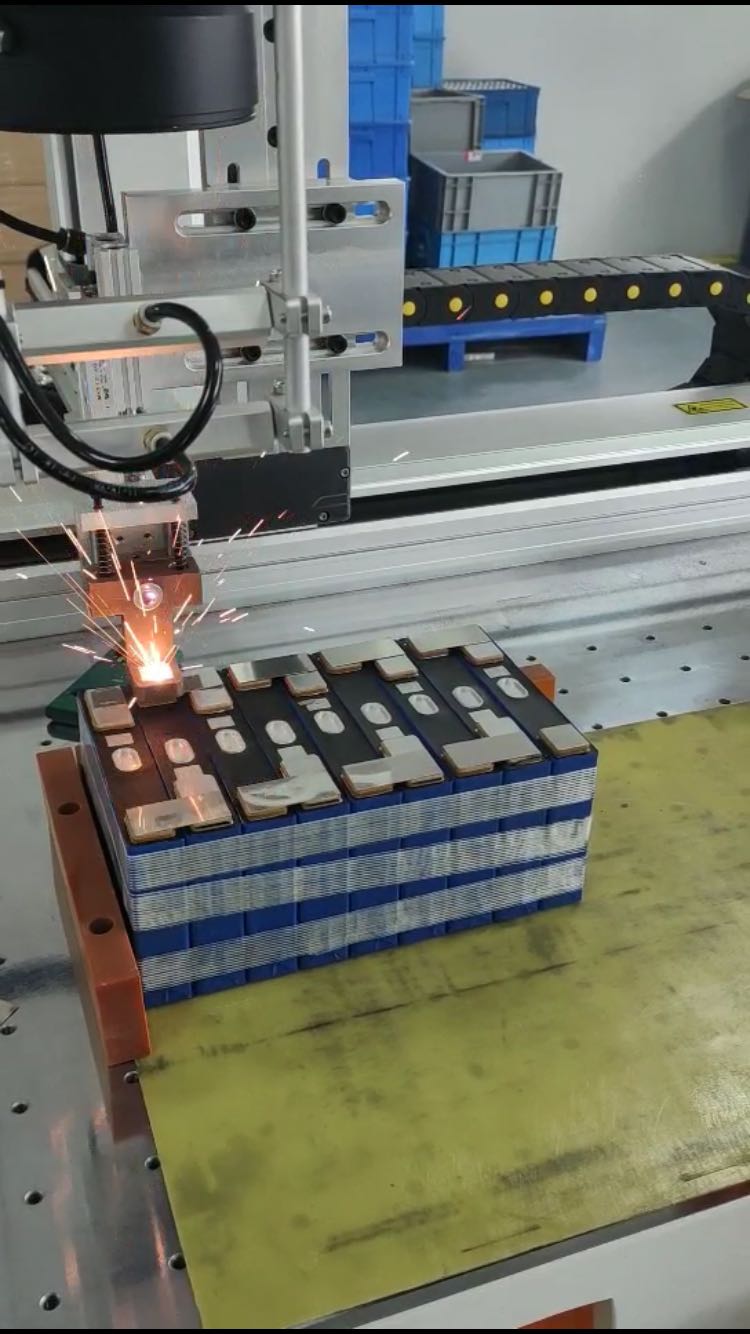

Battery pole welding: There is an electrode on the cover plate of the battery, which is composed of two parts connecting the internal and external parts of the battery. The internal connection of the battery is the welding between the electrodes of the battery core and the cover plate, while on the outside of the battery, the electrode column is welded together with the connecting plate to form a series and parallel circuit. A battery's electrode columns are positive and negative, usually made of aluminum, while the negative is made of copper. Usually riveted, riveted after the completion of full welding, size is generally 8 circle. In the welding process, on the premise of ensuring the pull-up and electrical conductivity, high-quality, evenly distributed fiber laser or composite welding laser should be selected. The use of fiber laser and composite welding laser can realize the aluminum-aluminum structure, improve the welding quality, reduce spatter, and improve the welding quality. Xinde Laser laser welding equipment can be very good welding battery pole ear pole.

Joint welding: Joints and joints are an important part of connecting the battery cover to the cell. The method should not only take into account the overcurrent performance, strength and low splash performance of the battery, but also ensure that it will not fall onto the battery core when welding with the cover plate, so as to avoid short circuit. Copper is a negative electrode material, which is a high reaction material with low attraction.

Battery pole welding: There is an electrode on the cover plate of the battery, which is composed of two parts connecting the internal and external parts of the battery. The internal connection of the battery is the welding between the electrodes of the battery core and the cover plate, while on the outside of the battery, the electrode column is welded together with the connecting plate to form a series and parallel circuit. A battery's electrode columns are positive and negative, usually made of aluminum, while the negative is made of copper. Usually riveted, riveted after the completion of full welding, size is generally 8 circle. In the welding process, on the premise of ensuring the pull-up and electrical conductivity, high-quality, evenly distributed fiber laser or composite welding laser should be selected. The use of fiber laser and composite welding laser can realize the aluminum-aluminum structure, improve the welding quality, reduce spatter, and improve the welding quality. Xinde Laser laser welding equipment can be very good welding battery pole ear pole.

Joint welding: Joints and joints are an important part of connecting the battery cover to the cell. The method should not only take into account the overcurrent performance, strength and low splash performance of the battery, but also ensure that it will not fall onto the battery core when welding with the cover plate, so as to avoid short circuit. Copper is a negative electrode material, which is a high reaction material with low attraction.

Shell sealing: power battery shell is made of aluminum alloy, stainless steel, mainly aluminum alloy, rarely use pure aluminum. Stainless steel is the best laser welding material for lasers. Better welding results can be obtained by using pulse or continuous laser. Using continuous laser to weld thin shell lithium battery, the efficiency can be increased by 5~10 times, and it has good appearance and sealing performance.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top