New energy PACK whole line solution provider

Fiber laser brings technological innovation to industry

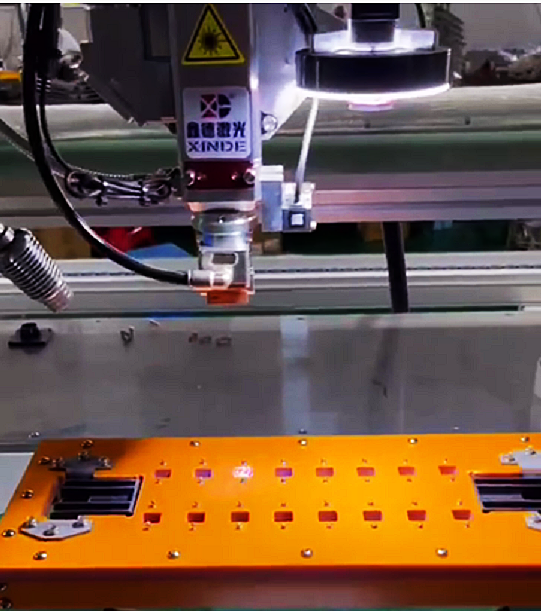

With the development of industry and the progress of production technology, a variety of fiber laser production equipment has been introduced, as the representative of the third generation of laser technology, fiber laser to industry what are the benefits?

1. because the fiber laser in the cavity without the use of optical lens, so no adjustment, no maintenance, high stability. Xinde Laser welding equipment laser and Dazu laser use the same brand supplier - Chuangxin laser.

2. optical fiber output technology, so that the fiber laser can easily achieve a variety of multidimensional, arbitrary space processing, simplifying the design of mechanical system.

3. high power, the fiber laser used in the market now is 6000 watts. Xinde laser laser welding machine the largest fiber laser power is 6000 watts, such as gantry continuous laser welding machine, gantry galvanometer laser welding machine, manipulator laser welding machine, water through laser welding machine and other models have 6000 watts of power.

4. Because of the energy level of rare earth ions and various types of rare earth ions, the wavelength of the output laser is longer. The machine wavelength of the welding equipment of Xinde laser is 1070nm.

5. there is no need to use the temperature difference conductance cooling or water cooling, only a simple air cooling.

6. high electro-optic efficiency, electro-optic comprehensive utilization rate can reach 20%, in the process of work to save a lot of power, save the operation cost.

7. adapt to the harsh working environment, dust, vibration, impact, temperature, humidity has a high tolerance.

It can be seen that fiber laser to industry has a huge benefit, fiber laser can not only bring technical innovation for industry, but also can ensure the production process of products.

Xinde Laser laser welding machine in the field of lithium battery welding has 12 years of dedicated experience, can ensure the quality of lithium battery welding process and beautiful.

1. because the fiber laser in the cavity without the use of optical lens, so no adjustment, no maintenance, high stability. Xinde Laser welding equipment laser and Dazu laser use the same brand supplier - Chuangxin laser.

2. optical fiber output technology, so that the fiber laser can easily achieve a variety of multidimensional, arbitrary space processing, simplifying the design of mechanical system.

3. high power, the fiber laser used in the market now is 6000 watts. Xinde laser laser welding machine the largest fiber laser power is 6000 watts, such as gantry continuous laser welding machine, gantry galvanometer laser welding machine, manipulator laser welding machine, water through laser welding machine and other models have 6000 watts of power.

4. Because of the energy level of rare earth ions and various types of rare earth ions, the wavelength of the output laser is longer. The machine wavelength of the welding equipment of Xinde laser is 1070nm.

5. there is no need to use the temperature difference conductance cooling or water cooling, only a simple air cooling.

6. high electro-optic efficiency, electro-optic comprehensive utilization rate can reach 20%, in the process of work to save a lot of power, save the operation cost.

7. adapt to the harsh working environment, dust, vibration, impact, temperature, humidity has a high tolerance.

It can be seen that fiber laser to industry has a huge benefit, fiber laser can not only bring technical innovation for industry, but also can ensure the production process of products.

Xinde Laser laser welding machine in the field of lithium battery welding has 12 years of dedicated experience, can ensure the quality of lithium battery welding process and beautiful.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top