Yi Jianqiang, a researcher at the China Institute of Automation, told reporters, "I am very happy to see this data. In recent years, China's industrial robots have developed rapidly and become a big consumer market in the world."

With the rapid development of intelligent manufacturing in China, many industrial problems have gradually emerged, such as: difficult to recruit workers, high cost of employment. As a result, many far-sighted enterprises have started to replace human workers with robots, thus setting off a robot boom in China.

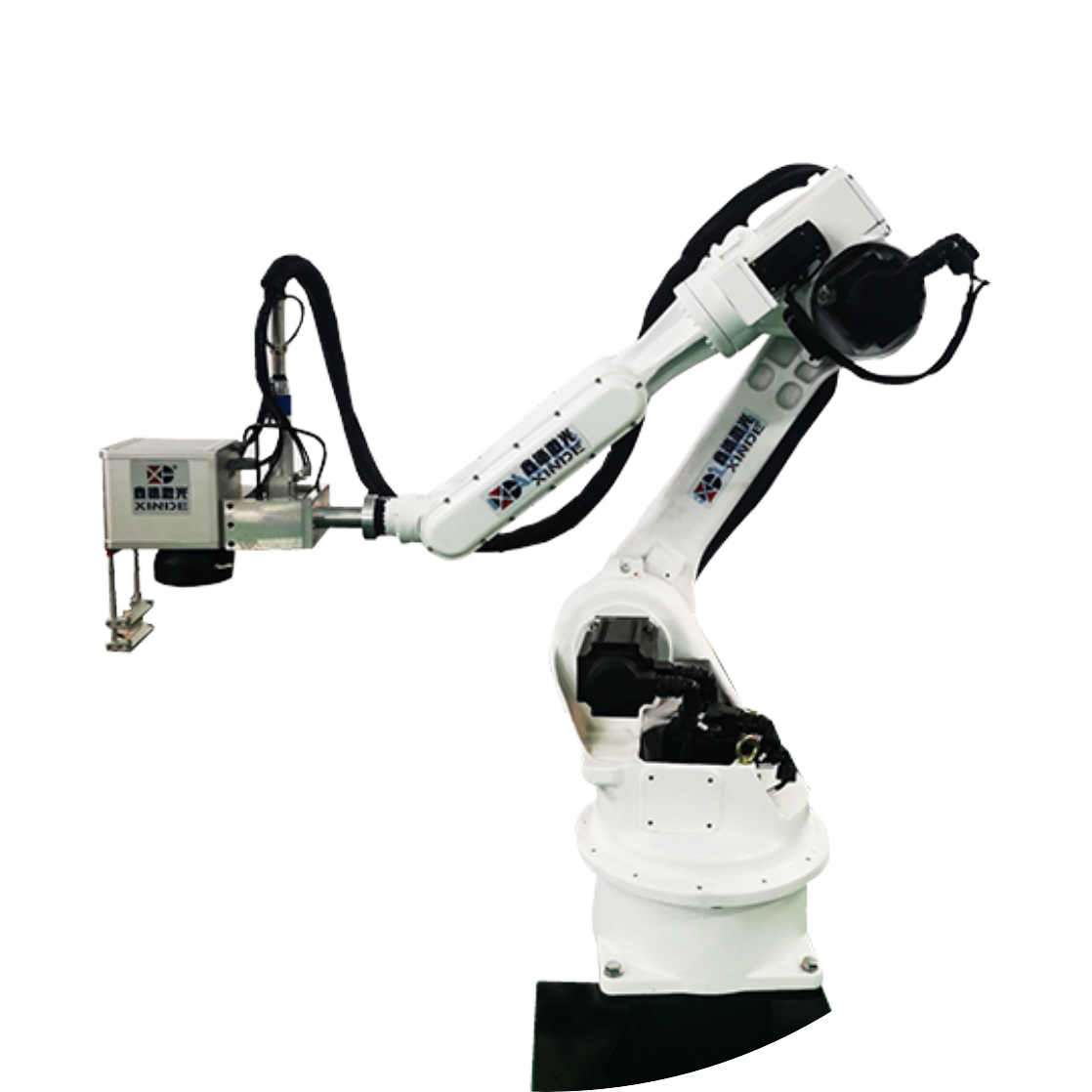

The robot has great advantages. It can carry out arbitrary welding action and weld multiple stations simultaneously within the effective range of the arm span, with high productivity and efficiency.

Xinde Laser's six-axis robot continuous laser welding machine adopts ABB Germany's international first-class brand six-axis robot as the movement body, humanized operating system, easy to learn.

Not only that, the welding equipment has a wide range of applications: it is suitable for large surface welding of new energy lithium battery PACK, flip sheet, pole lug pole, explosion-proof sheet, soft connection of the confluence bar, a variety of large size power battery housing and other laser welding.

According to the "Operation of Robot Industry from January to December 2020" released by the Ministry of Industry and Information, the cumulative production of 237,000 sets of industrial robots in 2020, with a year-on-year growth of 19.1%, set a record for the annual output per unit production of industrial robots in China, and the manufacturing in China is upgrading to "intelligent manufacturing in China".

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top