New energy PACK whole line solution provider

Explore the profound knowledge in the positive and negative terminals of the battery ear! Do you know all about it?

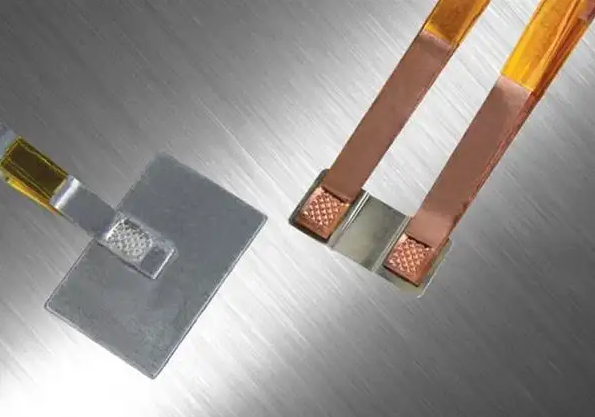

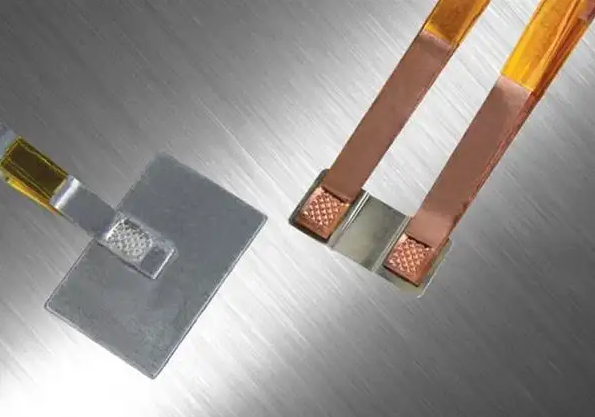

The polar ear is a raw material for lithium-ion polymer battery products, such as the Bluetooth of mobile phones, Bluetooth batteries and laptop batteries used in our life.

Lithium battery is divided into positive and negative electrodes, and the electrode ear is the metal conductive body that leads the positive and negative electrodes from the battery core. Generally speaking, the positive and negative electrode ears of the battery contact point when charging and discharging (just like we want to breathe through the nose), but this contact point is not the copper sheet on the surface of the battery, but a connection inside the battery. The anode ear is generally divided into three kinds of materials. The positive electrode of the battery uses aluminum (Al) material, the negative electrode uses nickel (Ni) material, and there are also copper plated nickel (Ni-Cu) material. They are made of two parts of the composite film and metal strip.

So why do lithium-ion batteries use aluminum for the positive end and nickel for the negative end?

1. The use of both for fluid collection is because of their good electrical conductivity, soft texture (perhaps also conducive to bonding), is relatively common and cheap, and the surface of both can form a layer of oxide protective film.

2. Copper/nickel surface oxide layer belongs to semiconductor, electron conduction, oxidation layer is too thick, impedance is large; And aluminum surface oxide layer of alumina is an insulator, the oxide layer can not conduct electricity, but because it is very thin, through the tunnel effect of electronic conductance, if the oxide layer is thick, aluminum foil conductivity is very poor, even insulation. General fluid collection in the use of the best surface cleaning, on the one hand to wash away the oil, but also to remove the thick oxide layer.

3. High positive electrode potential, aluminum thin oxidation layer is very dense, can prevent fluid oxidation. The thin oxide layer of copper/nickel is more loose, in order to prevent its oxidation, and it is difficult for lithium to form lithium embedded alloy with copper/nickel at low potential. However, if the surface of copper/nickel is oxidized in large amounts, lithium will react with copper oxide/nickel at slightly higher potential, and aluminum foil cannot be used as a negative electrode, lithium aluminization will occur at low potential.

4. Fluid collection requires pure composition. The composition of aluminum is not pure, which will lead to the surface film is not dense and point corrosion occurs, more than the destruction of the surface film leads to the production of lithium aluminum alloy.

To sum up, is the battery positive with aluminum, negative nickel pay attention to.

Lithium battery is divided into positive and negative electrodes, and the electrode ear is the metal conductive body that leads the positive and negative electrodes from the battery core. Generally speaking, the positive and negative electrode ears of the battery contact point when charging and discharging (just like we want to breathe through the nose), but this contact point is not the copper sheet on the surface of the battery, but a connection inside the battery. The anode ear is generally divided into three kinds of materials. The positive electrode of the battery uses aluminum (Al) material, the negative electrode uses nickel (Ni) material, and there are also copper plated nickel (Ni-Cu) material. They are made of two parts of the composite film and metal strip.

So why do lithium-ion batteries use aluminum for the positive end and nickel for the negative end?

1. The use of both for fluid collection is because of their good electrical conductivity, soft texture (perhaps also conducive to bonding), is relatively common and cheap, and the surface of both can form a layer of oxide protective film.

2. Copper/nickel surface oxide layer belongs to semiconductor, electron conduction, oxidation layer is too thick, impedance is large; And aluminum surface oxide layer of alumina is an insulator, the oxide layer can not conduct electricity, but because it is very thin, through the tunnel effect of electronic conductance, if the oxide layer is thick, aluminum foil conductivity is very poor, even insulation. General fluid collection in the use of the best surface cleaning, on the one hand to wash away the oil, but also to remove the thick oxide layer.

3. High positive electrode potential, aluminum thin oxidation layer is very dense, can prevent fluid oxidation. The thin oxide layer of copper/nickel is more loose, in order to prevent its oxidation, and it is difficult for lithium to form lithium embedded alloy with copper/nickel at low potential. However, if the surface of copper/nickel is oxidized in large amounts, lithium will react with copper oxide/nickel at slightly higher potential, and aluminum foil cannot be used as a negative electrode, lithium aluminization will occur at low potential.

4. Fluid collection requires pure composition. The composition of aluminum is not pure, which will lead to the surface film is not dense and point corrosion occurs, more than the destruction of the surface film leads to the production of lithium aluminum alloy.

To sum up, is the battery positive with aluminum, negative nickel pay attention to.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top