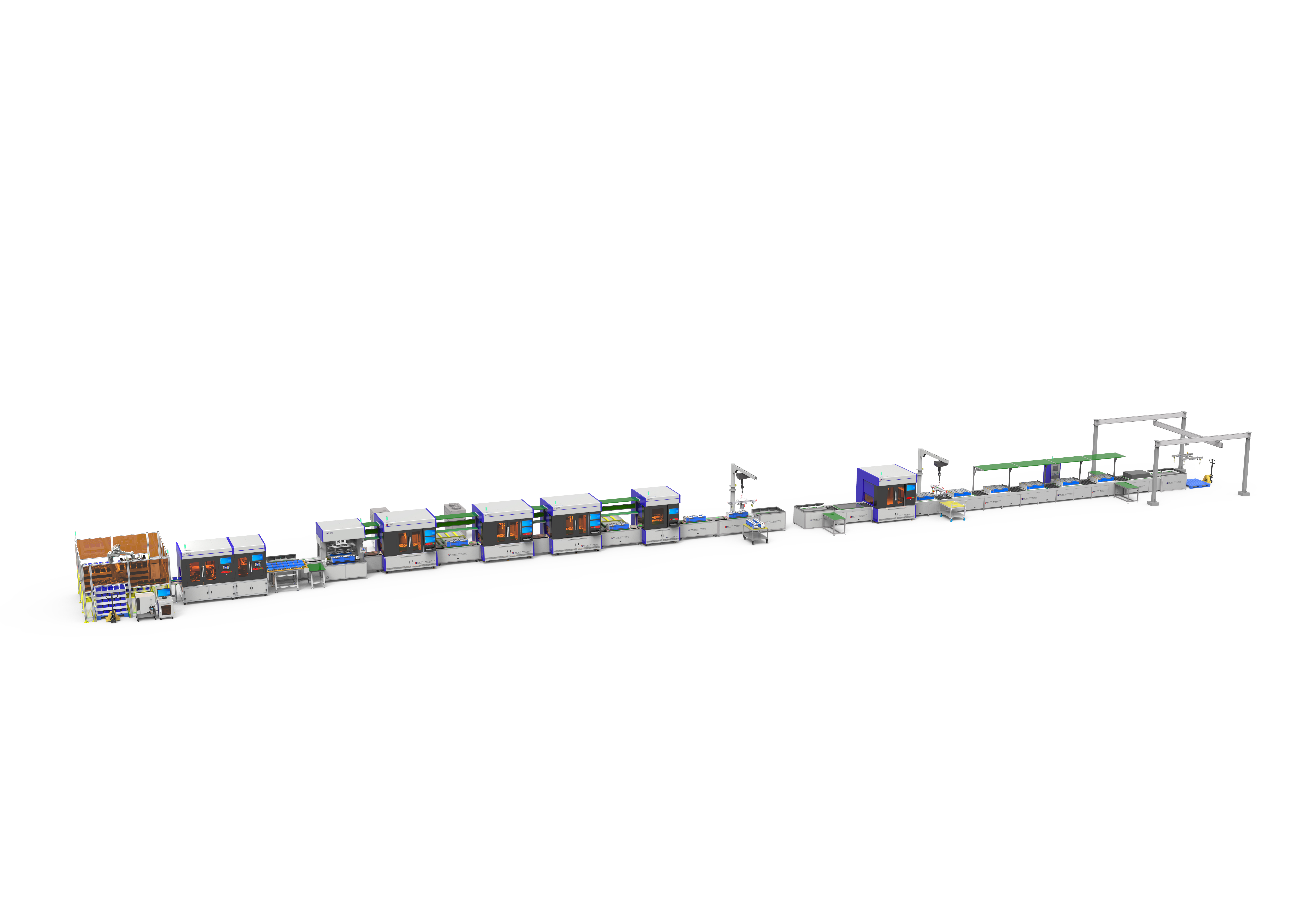

Applied to power battery PACK/energy storage battery pack square aluminum shell core pack assembly, by the upper and lower double double speed chain line. The whole line is divided into PACK assembly line and module assembly line. The key units are: mechanical hand material, sorting machine, extrusion and strapping, CCD polarity detection, laser cleaning, side plate welding, Busbar welding, total pressure insulation test, GN bad discharge mechanism, the main body of the total assembly line, etc., which can be customized according to user requirements.

Advantages of Equipment

modularization

Key unit modular, easy installation and maintenance, according to the actual production needs of the process free combination, simple and convenient operation

High efficiency

Up and down circulation line transmission, pipeline type, efficient standardization

intelligence

Intelligent operating system, scientific management, strong visitor

Equipment Parameters

|

Project Name |

Data Parameters |

|

Overall line dimensions |

Custom/reference size:45M*3.5M*2.2M(L*W*H) |

|

Compatible cell range |

Famous brand square aluminum shell cell |

|

Production line capacity efficiency |

300-500 Group/day |

Battery module

|

|

|

|

|

|

|

|

|

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top