New energy PACK whole line solution provider

New energy lithium battery pack production line intelligent manufacturing expert -- Xinde laser

Electric vehicles are one of the main themes of the current social development, and all countries are seizing the strategic commanding heights of new energy vehicles.

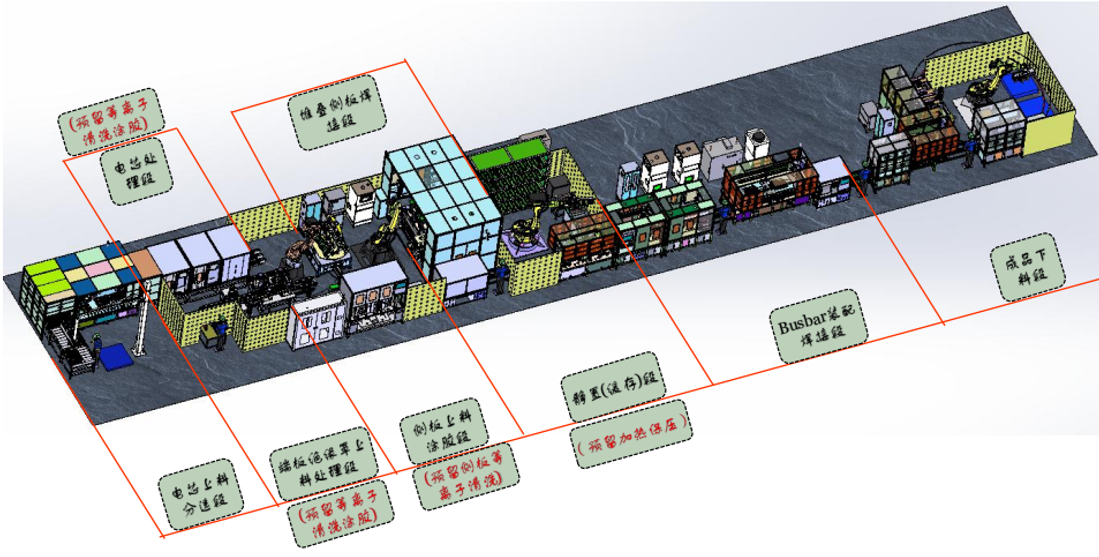

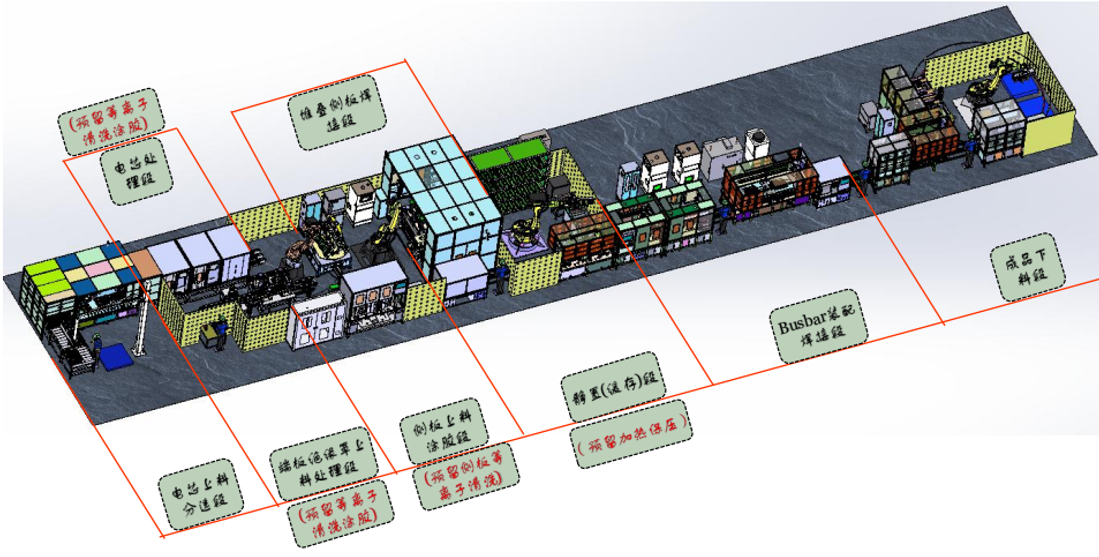

As a new era of new energy pack production line intelligent manufacturing experts, Xinde Laser developed the square shell soft PACK module automatic production line.

1. Manual feeding

At the beginning of the process, the electric core is manually fed, taken out from the box and placed on the belt line, which is transmitted to the truss platform through the belt line. The truss platform is composed of YZ biaxial. The clamp is equipped with a fixed reader and probe for voltage internal resistance test.

2. Manual glue

The electric core flowing down the front OK belt shall be manually removed for adhesive treatment, then put down and placed on the upper belt line for stacking.

Work station 3. Manual stacking

After gluing, the core flows down, and the core is taken manually to complete the stack on the line.

Work station 4. Manual labeling

The first station flowing from the lifting platform into the line body is used as the manual module labeling, so as to facilitate subsequent polarity detection, laser welding, and post-welding detection data recording.

5. Polarity detection of mold assembly before welding

After entering the visual identification station, take pictures of visual identification to eliminate the welding problem due to the wrong order of positive and negative electrodes. Its advantages are accurate monitoring, data stability, detection data uploaded to the top machine, can monitor real-time data in detail.

Station 6. Side plate welding

The group of cells transferred from the stacking station are placed into the extruding station and side plates are placed. After the extruder station is positioned, the side plate is welded by the mechanical arm. After the welding is completed, the extruder station is reset and transferred to the assembly line by the mechanical arm.

Station 7. Pole welding

After the aluminum row is placed, the blocking cylinder is released, the module moves forward to the welding position, the welding sensor senses the module to be welded, the jacking cylinder lifts the tray top, gives the laser welding machine welding signal after the jacking is completed, and then the visual equipment carries out the feature capture to improve the welding progress. After the capture is completed, the laser welding is carried out.

Work station 8. Pressure and internal resistance test

After the aluminum bar is welded, the post-welding voltage insulation test is entered. The principle is to add a higher than normal working voltage to the insulation of the tested equipment for a specified period of time. The voltage added to the above will only produce a small leakage current, so the insulation is better. Through testing, the material can be dropped for back-end pre-market product testing.

Station 9. FPC welding

After the pole welding is completed, two stations will be reserved for FPC welding preparation process, and the modification process will be changed according to customer requirements. Galvanometer laser welding joint, welding speed and high precision

10. Unloading of balanced boom

After the completion of the post-welding eye inspection, it flows into the rear lifting platform. Due to the large mass of the module, the daily work intensity of manual cutting is too high, so the balanced boom is used to grab the cutting. After the cutting, the pallet is lowered into the lower speed chain under the lifting platform and sent to the front lifting platform.

Xinde Laser focuses on new energy lithium battery laser welding equipment and pack automated assembly line!

As a new era of new energy pack production line intelligent manufacturing experts, Xinde Laser developed the square shell soft PACK module automatic production line.

1. Manual feeding

At the beginning of the process, the electric core is manually fed, taken out from the box and placed on the belt line, which is transmitted to the truss platform through the belt line. The truss platform is composed of YZ biaxial. The clamp is equipped with a fixed reader and probe for voltage internal resistance test.

2. Manual glue

The electric core flowing down the front OK belt shall be manually removed for adhesive treatment, then put down and placed on the upper belt line for stacking.

Work station 3. Manual stacking

After gluing, the core flows down, and the core is taken manually to complete the stack on the line.

Work station 4. Manual labeling

The first station flowing from the lifting platform into the line body is used as the manual module labeling, so as to facilitate subsequent polarity detection, laser welding, and post-welding detection data recording.

5. Polarity detection of mold assembly before welding

After entering the visual identification station, take pictures of visual identification to eliminate the welding problem due to the wrong order of positive and negative electrodes. Its advantages are accurate monitoring, data stability, detection data uploaded to the top machine, can monitor real-time data in detail.

Station 6. Side plate welding

The group of cells transferred from the stacking station are placed into the extruding station and side plates are placed. After the extruder station is positioned, the side plate is welded by the mechanical arm. After the welding is completed, the extruder station is reset and transferred to the assembly line by the mechanical arm.

Station 7. Pole welding

After the aluminum row is placed, the blocking cylinder is released, the module moves forward to the welding position, the welding sensor senses the module to be welded, the jacking cylinder lifts the tray top, gives the laser welding machine welding signal after the jacking is completed, and then the visual equipment carries out the feature capture to improve the welding progress. After the capture is completed, the laser welding is carried out.

Work station 8. Pressure and internal resistance test

After the aluminum bar is welded, the post-welding voltage insulation test is entered. The principle is to add a higher than normal working voltage to the insulation of the tested equipment for a specified period of time. The voltage added to the above will only produce a small leakage current, so the insulation is better. Through testing, the material can be dropped for back-end pre-market product testing.

Station 9. FPC welding

After the pole welding is completed, two stations will be reserved for FPC welding preparation process, and the modification process will be changed according to customer requirements. Galvanometer laser welding joint, welding speed and high precision

10. Unloading of balanced boom

After the completion of the post-welding eye inspection, it flows into the rear lifting platform. Due to the large mass of the module, the daily work intensity of manual cutting is too high, so the balanced boom is used to grab the cutting. After the cutting, the pallet is lowered into the lower speed chain under the lifting platform and sent to the front lifting platform.

Xinde Laser focuses on new energy lithium battery laser welding equipment and pack automated assembly line!

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top