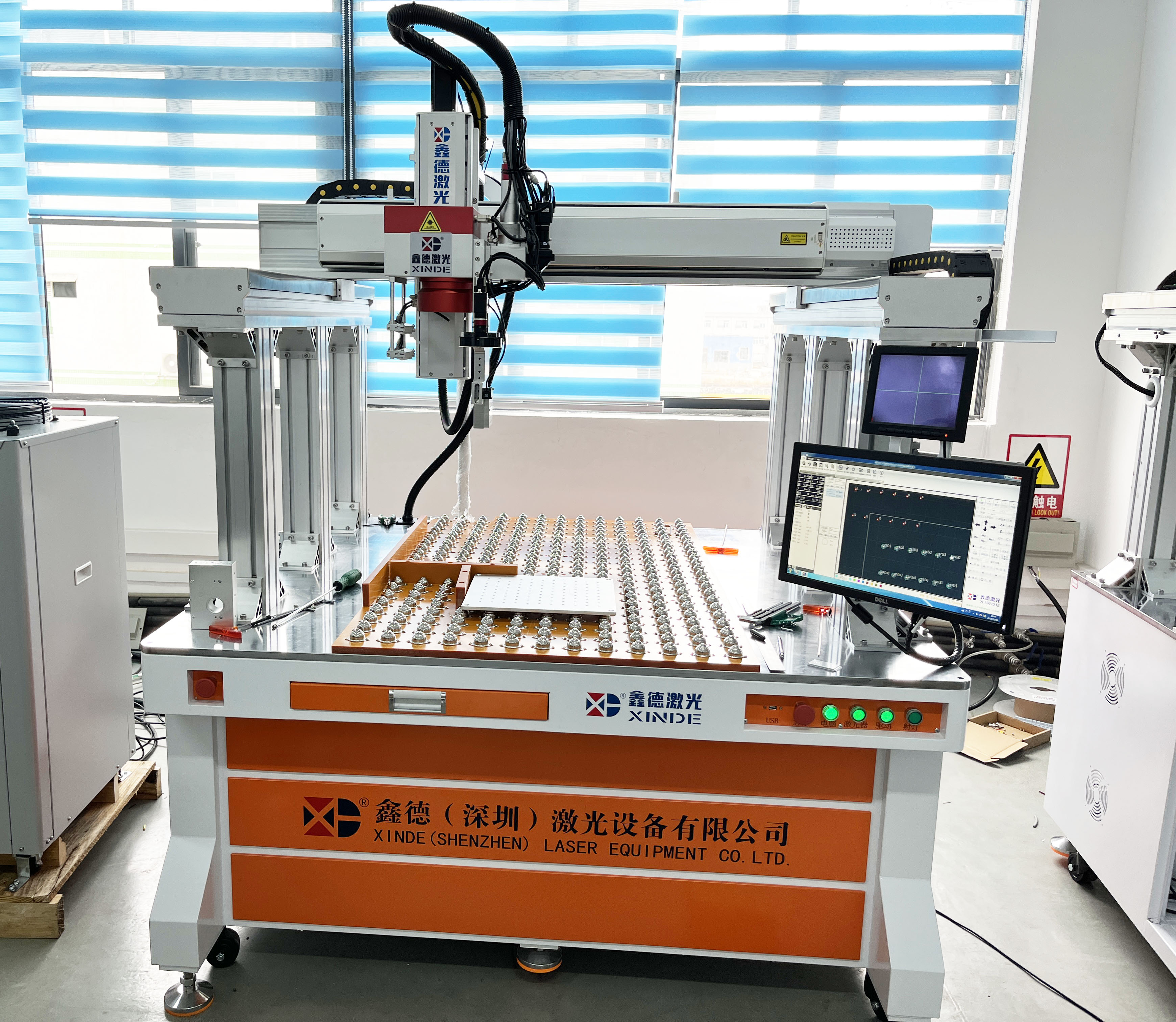

Today, I will focus on introducing the gantry large-format continuous laser welding machine of XindeL Laser to explore why it can become the core favorite of many manufacturers of welded square shell stud lithium batteries.

First of all, make a simple self-introduction to the model:

Longmen large field laser welding machine adopts 1500-6000 watt fiber laser, the laser electro-optic conversion rate is high, laser life is long, is the current photoelectric conversion energy of the highest laser. The laser welding machine adopts gantry structure, automatic lifting laser beam, based on the windows system welding software, welding path can be freely modified, simple and convenient operation, lithium battery pack welding process shows great advantages.

What are the characteristics of gantry large-format continuous laser welding machine?

1. Gantry structure can be large-scale welding, at the same time install multiple sets of fixture, can be welded various specifications of lithium battery pack.

2. Laser welding spot fine, high penetration, small taper, high precision, smooth welding surface effect without bubbles.

3. Laser welding processing is pollution-free, small heat affected zone, small deformation, water cooling system, to ensure the life of the laser.

4. Hd CCD monitoring screen, red light positioning indicator, welding programming and debugging process is simple and convenient.

What are the welding advantages of using gantry large-format continuous laser welding machine?

1. The welder material deformation is small, the equipment performance is stable, easy to operate, welding quality is superior, high degree of automation.

2. High laser focusing energy and adjustable power. Non-contact welding mode, laser head welding process is not interfered by fixture obstruction.

3. Power lithium battery has pressure resistance and leakage test requirements, in addition, copper and aluminum materials are difficult to weld characteristics, can be easily solved by laser welding, to ensure the safety and certainty of the battery pack.

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top