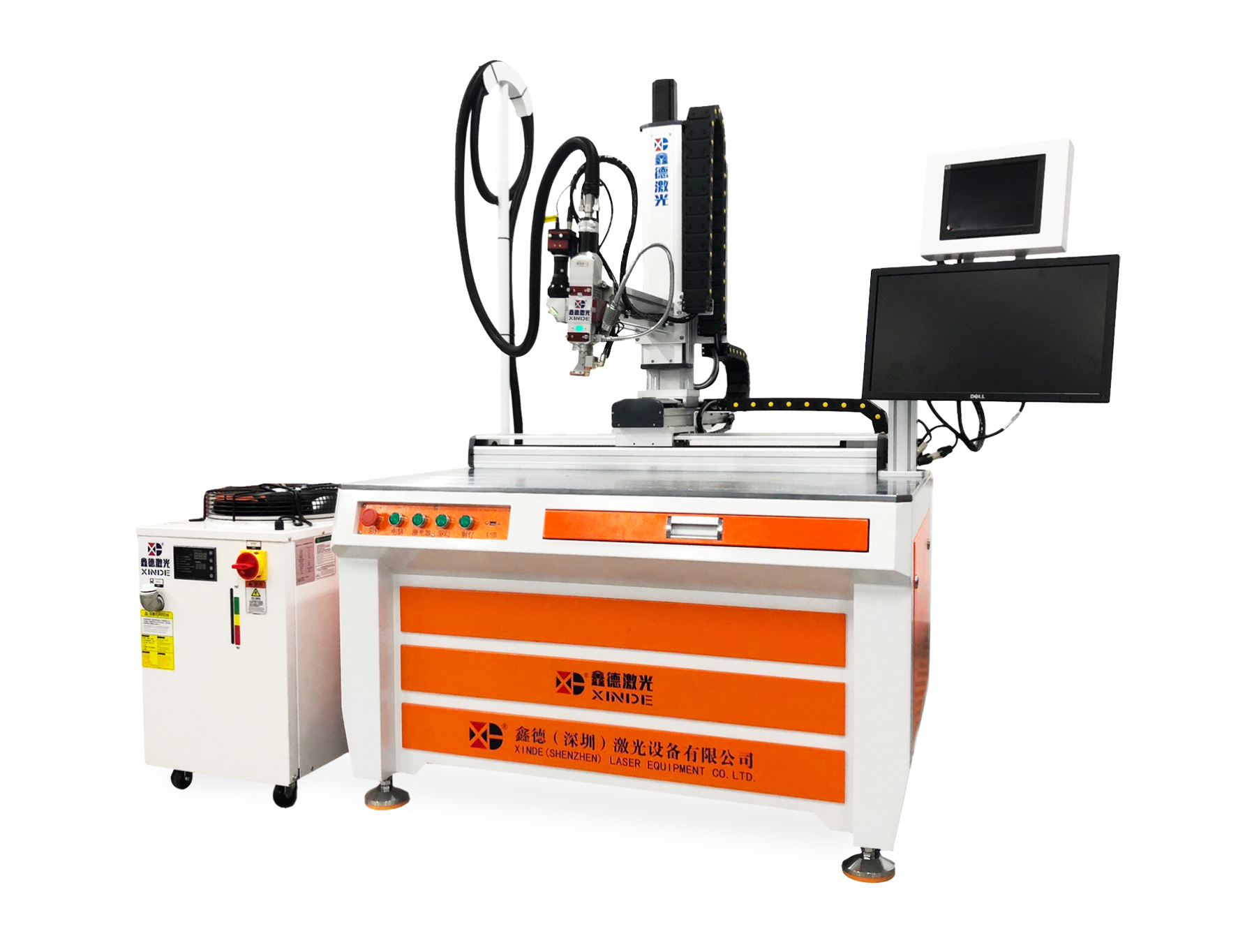

New energy PACK whole line solution provider

Why should the manufacturing industry introduce laser welding automation equipment?

Irritated irritated irritated, prices are rising, labor costs in raising, sharp lack of human resources, become the various industry facing the severe test of this phenomenon by the electronics industry is outstanding, order a lot but out of stock, very headache.

Therefore, lithium battery laser welding manufacturers Xin De laser think: to solve this phenomenon is to rely on automation equipment to make up for this point, automation equipment can replace people save people, originally three to five people to do it can be completed and the efficiency is several times that of people, it is not afraid of personnel replacement of proficiency, just switch button start can work. The orders can be completed on time and the shipment is smooth, so the lost orders can be retrieved because the goods cannot be delivered on time before. It can not only improve production efficiency, but also improve enterprise efficiency. Therefore, it is a wise choice for manufacturing enterprises to introduce automation equipment.

Plus personnel change frequently, the new skilled level formed can not produce goods or overtime to catch shipment, resulting in employees every day to work overtime, every day to extend the time class, employees are physically and mentally tired, over time will have the idea of resignation, this kind of repeated personnel replacement formed a order can not produce the goods situation.

Therefore, lithium battery laser welding manufacturers Xin De laser think: to solve this phenomenon is to rely on automation equipment to make up for this point, automation equipment can replace people save people, originally three to five people to do it can be completed and the efficiency is several times that of people, it is not afraid of personnel replacement of proficiency, just switch button start can work. The orders can be completed on time and the shipment is smooth, so the lost orders can be retrieved because the goods cannot be delivered on time before. It can not only improve production efficiency, but also improve enterprise efficiency. Therefore, it is a wise choice for manufacturing enterprises to introduce automation equipment.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top