New energy PACK whole line solution provider

Under the wave of new energy, the production capacity of laser welding assisted power battery rises sharply

According to the way of battery packaging, battery can be divided into three types, namely cylindrical battery, square battery and soft-pack battery. The unit energy density, dead weight, internal resistance, cycle life, safety performance and other aspects of soft-pack battery are far superior to the other three kinds of battery. Even if there are safety problems, soft-pack battery only expands and cracks, and will not explode because of the use of metal shell. But because of poor consistency, high cost, high production process, lithium battery laser welding machine manufacturer Xinde laser analysis most of the domestic battery manufacturers will choose the lower cost of the square battery when entering the market. Data show that in 2021, square battery market share reached 86.4%, soft pack battery is 7.4%.

However, due to the growth of electric vehicle sales, the occurrence of spontaneous combustion of electric vehicles is frequent, coupled with the explosion of some storage stations in the past, the industry has to consider that the square battery as the main, the safety is slightly worse. Due to the continuous development of battery production technology in our country, and the key materials such as diaphragm are produced locally, the production cost of soft bag battery has reached the level of affordable. As consumers become more safety-conscious, soft-pack batteries perform well in safety and will return to the mainstream in the near future.

Thanks to the global trend of electrification, the capacity of power battery will continue to increase. Coupled with the increase of soft package penetration rate, the capacity of soft package will surpass the industry. From 2025 to 2030, the global demand for power battery will reach 556GWh and 1500GWh, compared with 113GWh at the end of 2019, with a growth rate of 31% and 27%. At the same time, due to the low penetration rate of soft-pack batteries in China, the shipment volume of soft-pack batteries will exceed the average growth of the industry in the future.

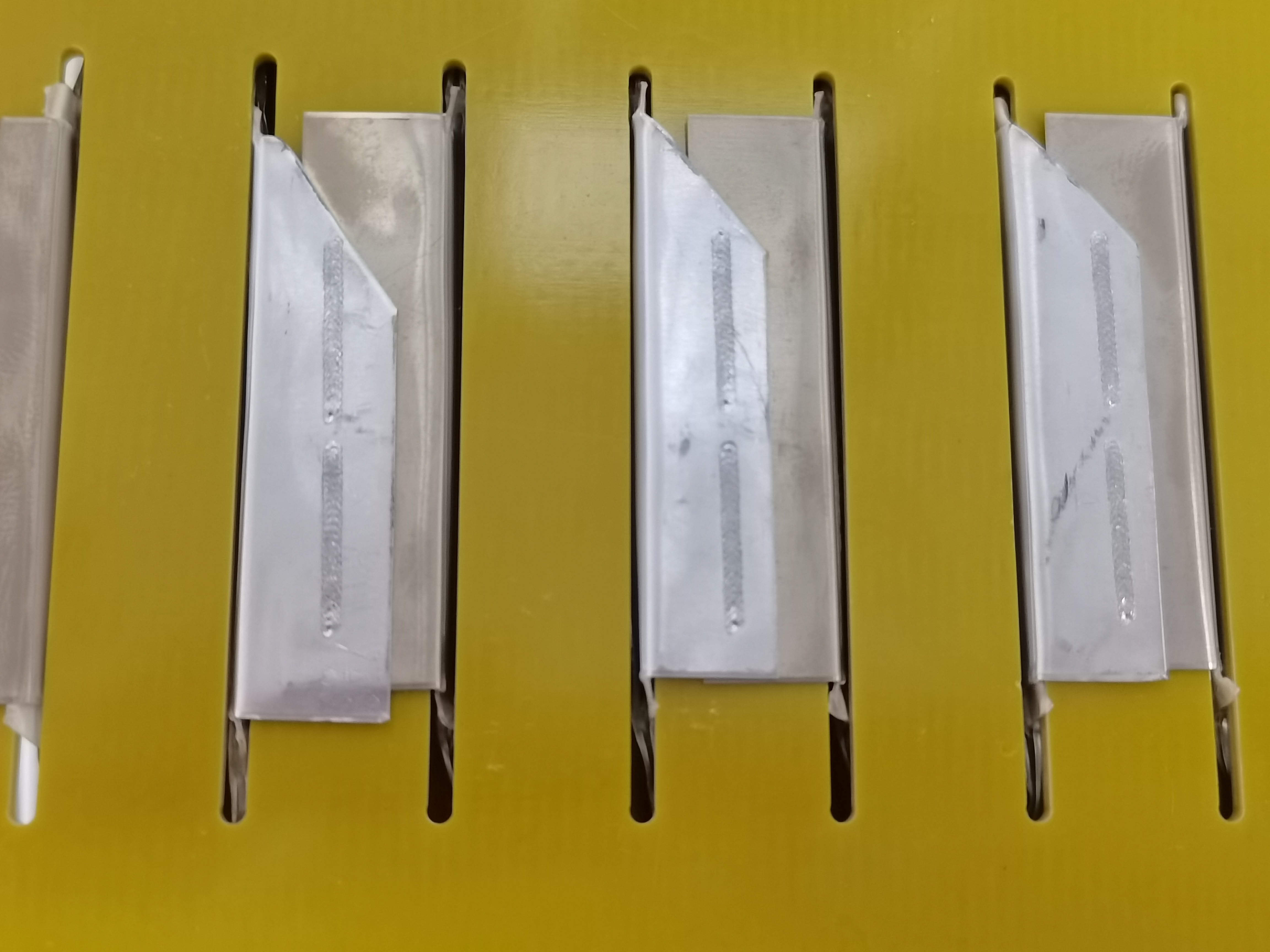

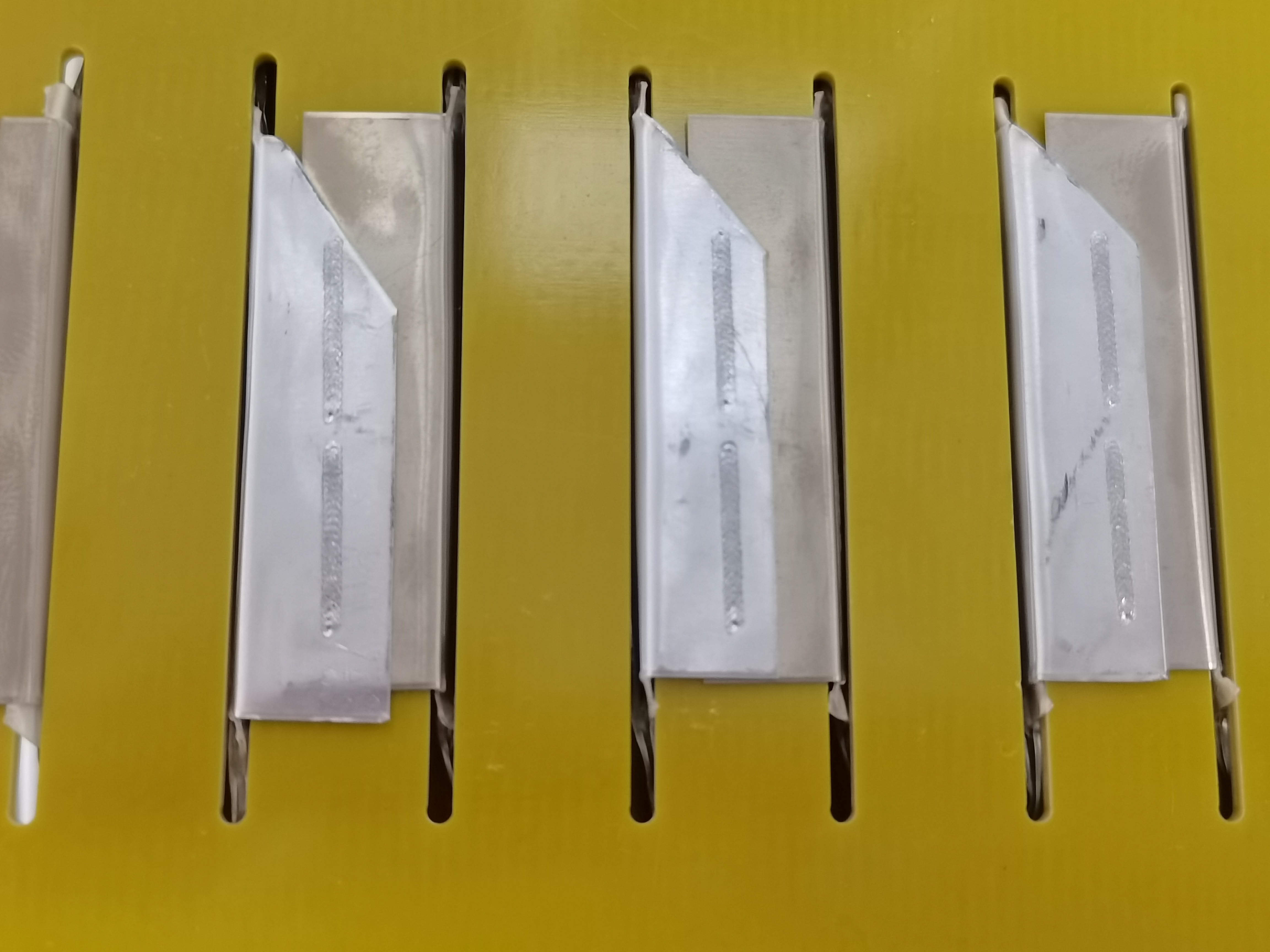

Flexible packaging lithium-ion battery has the advantages of high energy density, high safety, high conductivity, high rate, high cycle performance, etc., which is especially suitable for large-capacity power batteries, especially in the battery industry. Therefore, pole lug/busbar welding is an important link in the battery manufacturing process.

The laser welding equipment has greatly improved the welding efficiency of the soft-pack battery, and it is also the preferred welding equipment of many battery manufacturers.

Xinde Laser intelligent equipment has a large number of practical applications in the market of lithium battery welding process from square aluminum shell sealing welding, explosion-proof valve welding, convergence plate welding, liquid injection port welding, pole village collision welding, pole lug nickel welding, rotary studs welding, Busbar module welding, covering the overall scheme equipment of power battery PACK, energy storage battery fiber pack assembly line and assembly line. Customized according to the user, in line with the user's actual production needs, site requirements of the process solution, truly achieve the battery manufacturing enterprises to provide one-stop service, committed to the national new energy lithium battery industry development to make a positive contribution.

However, due to the growth of electric vehicle sales, the occurrence of spontaneous combustion of electric vehicles is frequent, coupled with the explosion of some storage stations in the past, the industry has to consider that the square battery as the main, the safety is slightly worse. Due to the continuous development of battery production technology in our country, and the key materials such as diaphragm are produced locally, the production cost of soft bag battery has reached the level of affordable. As consumers become more safety-conscious, soft-pack batteries perform well in safety and will return to the mainstream in the near future.

Thanks to the global trend of electrification, the capacity of power battery will continue to increase. Coupled with the increase of soft package penetration rate, the capacity of soft package will surpass the industry. From 2025 to 2030, the global demand for power battery will reach 556GWh and 1500GWh, compared with 113GWh at the end of 2019, with a growth rate of 31% and 27%. At the same time, due to the low penetration rate of soft-pack batteries in China, the shipment volume of soft-pack batteries will exceed the average growth of the industry in the future.

The laser welding equipment has greatly improved the welding efficiency of the soft-pack battery, and it is also the preferred welding equipment of many battery manufacturers.

Xinde Laser intelligent equipment has a large number of practical applications in the market of lithium battery welding process from square aluminum shell sealing welding, explosion-proof valve welding, convergence plate welding, liquid injection port welding, pole village collision welding, pole lug nickel welding, rotary studs welding, Busbar module welding, covering the overall scheme equipment of power battery PACK, energy storage battery fiber pack assembly line and assembly line. Customized according to the user, in line with the user's actual production needs, site requirements of the process solution, truly achieve the battery manufacturing enterprises to provide one-stop service, committed to the national new energy lithium battery industry development to make a positive contribution.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top