New energy PACK whole line solution provider

New energy storage is ready for development. Xinde laser turns risks into opportunities

In order to improve production capacity and accelerate market penetration, in recent years, domestic battery manufacturers have been trying their best, from land to factories, and then to tens of billions of private additions, all because of the rapid development of the new energy vehicle industry. However, at the industrial level, the crazy expansion of major battery enterprises is not only limited to the field of new energy, but also to the rapidly growing field of energy storage.

With the massive investment of new energy infrastructure, the peak dislocation of power generation and consumption makes its role in the whole energy cycle more and more obvious. In addition, as an important part of the energy cycle, energy storage technology has also got great support from the government. At present, influenced by policy, electricity price, permeability of new energy power generation, the development speed of energy storage industry in our country will double within the year.

As the energy storage market has multiplied, the assembly line technology of the PACK module production line has once again been recognized. This not only reduces labor costs for battery makers, but also greatly reduces their delivery time.

Xinde Laser Equipment Co., Ltd. is a focus on new energy lithium battery laser welding, by R & D, manufacturing, service in one of the automation intelligent equipment technology enterprises. The company has perfect production equipment, cutting-edge technical personnel team, perfect after-sales service system, equipment products have been widely used in many leading enterprises in the lithium battery industry, superior quality has been widely recognized and supported by customers.

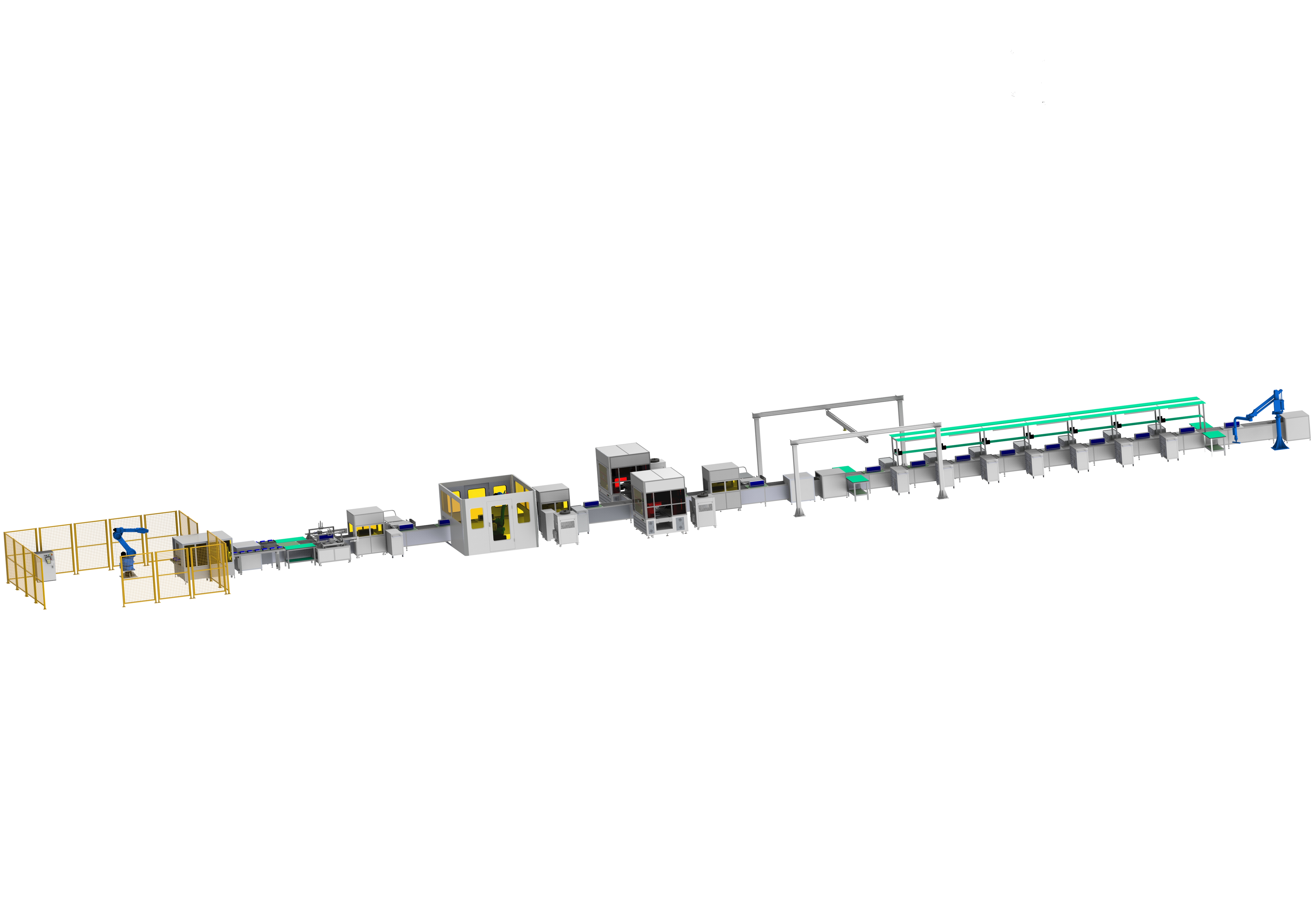

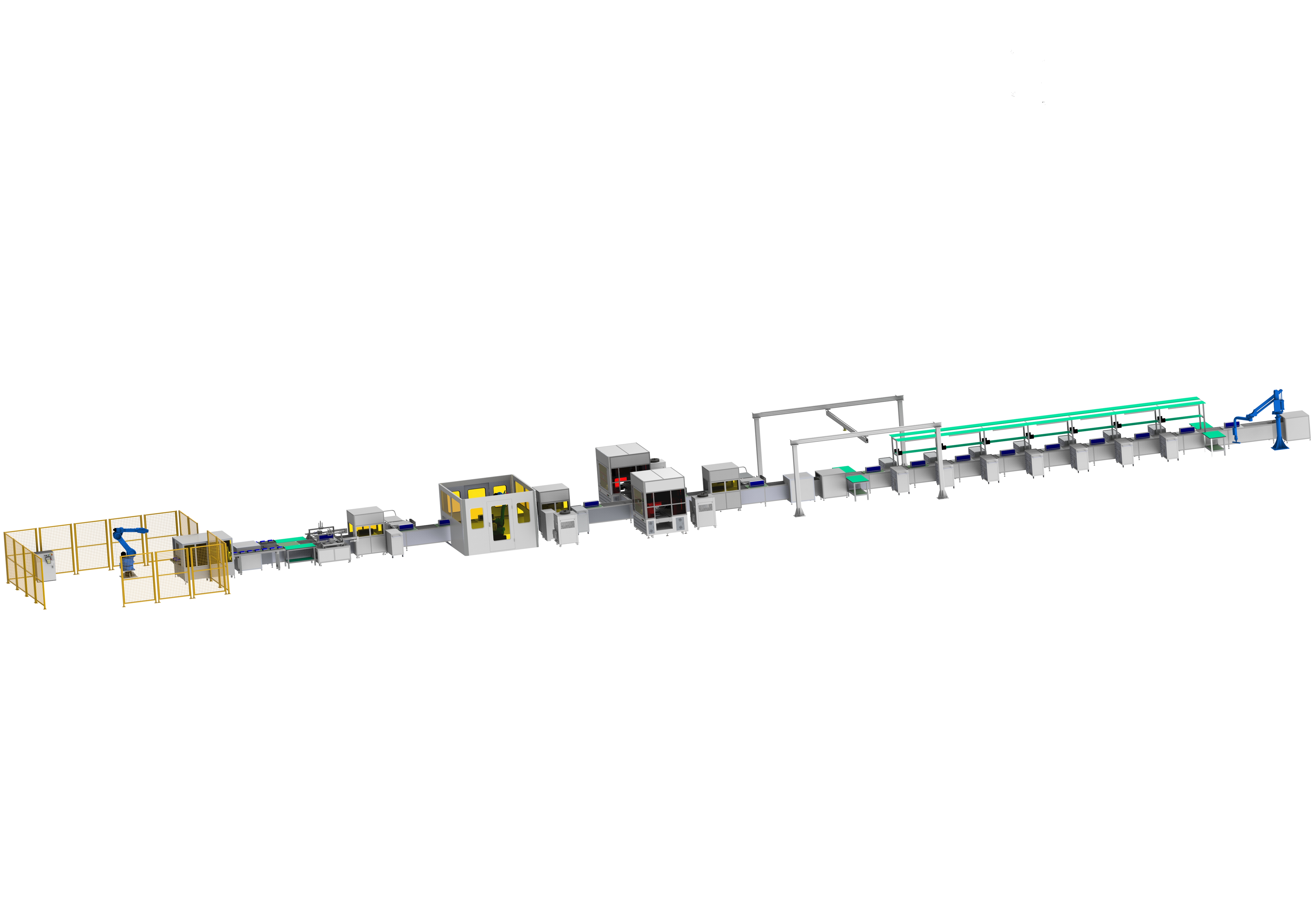

As a senior provider of new energy lithium battery welding equipment and PACK whole line solutions, Xinde Laser mainly researched and developed an automatic power battery module PACK production line this year, with the production line capacity efficiency of about 300-500 sets/day. Advantages of its equipment:

Modular - key unit modular, easy installation and maintenance, according to the actual production needs of the process free combination, simple and convenient operation;

High efficiency - up and down circulation line transmission, flow type, efficient standardization;

Intelligent - intelligent operating system, scientific management, strong visitor.

Recently, the overseas energy storage market has been in high demand, and our company's power battery PACK module assembly line has been exported constantly, which has solved the urgent problem of the manufacturers who are full of orders but lack of manpower.

In the face of the impact of the novel coronavirus on the global supply chain, Xinde Laser has made a forward-looking strategic reserve of core components. At the beginning of this year, despite the impact of the epidemic, Xinde Laser procurement, material transportation, personnel travel and other factors, the company will still do its best to support customers, turn risks into opportunities, and enhance customer stickiness.

With the massive investment of new energy infrastructure, the peak dislocation of power generation and consumption makes its role in the whole energy cycle more and more obvious. In addition, as an important part of the energy cycle, energy storage technology has also got great support from the government. At present, influenced by policy, electricity price, permeability of new energy power generation, the development speed of energy storage industry in our country will double within the year.

As the energy storage market has multiplied, the assembly line technology of the PACK module production line has once again been recognized. This not only reduces labor costs for battery makers, but also greatly reduces their delivery time.

Xinde Laser Equipment Co., Ltd. is a focus on new energy lithium battery laser welding, by R & D, manufacturing, service in one of the automation intelligent equipment technology enterprises. The company has perfect production equipment, cutting-edge technical personnel team, perfect after-sales service system, equipment products have been widely used in many leading enterprises in the lithium battery industry, superior quality has been widely recognized and supported by customers.

As a senior provider of new energy lithium battery welding equipment and PACK whole line solutions, Xinde Laser mainly researched and developed an automatic power battery module PACK production line this year, with the production line capacity efficiency of about 300-500 sets/day. Advantages of its equipment:

Modular - key unit modular, easy installation and maintenance, according to the actual production needs of the process free combination, simple and convenient operation;

High efficiency - up and down circulation line transmission, flow type, efficient standardization;

Intelligent - intelligent operating system, scientific management, strong visitor.

In the face of the impact of the novel coronavirus on the global supply chain, Xinde Laser has made a forward-looking strategic reserve of core components. At the beginning of this year, despite the impact of the epidemic, Xinde Laser procurement, material transportation, personnel travel and other factors, the company will still do its best to support customers, turn risks into opportunities, and enhance customer stickiness.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top