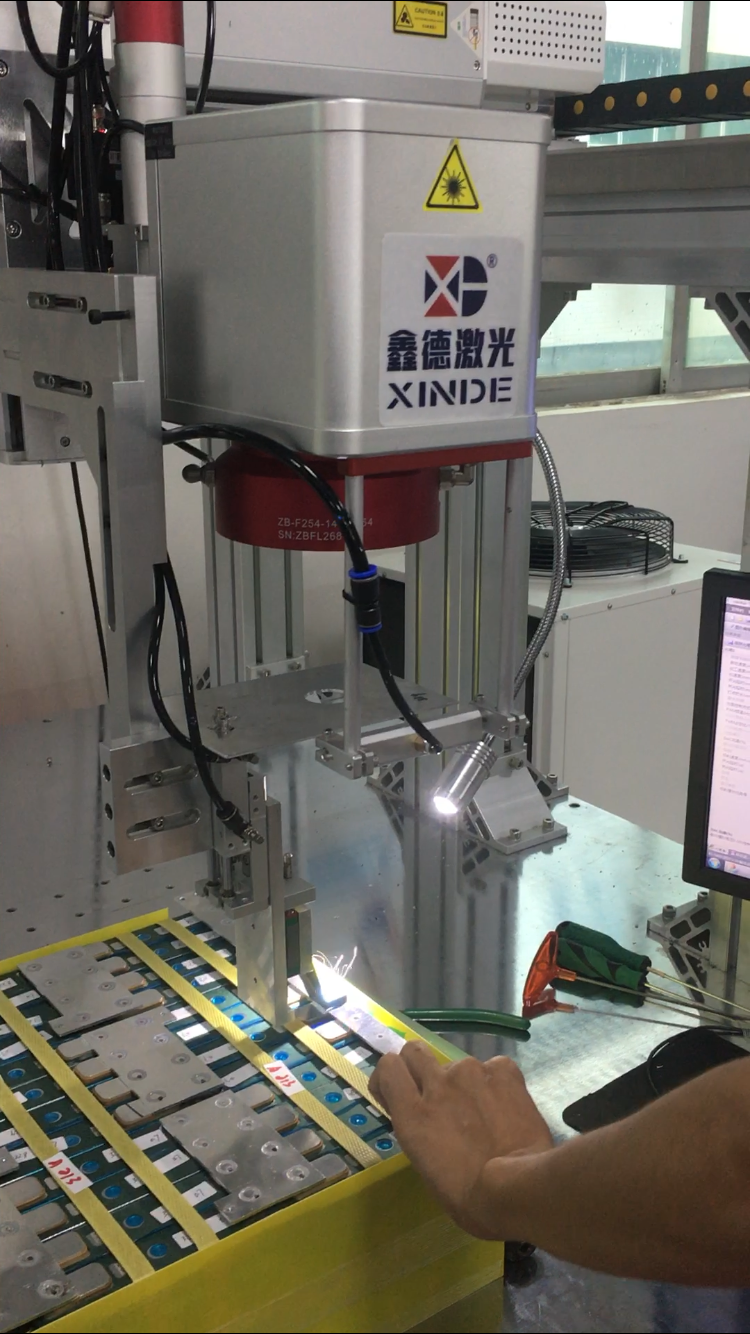

1. Soft wrap pole lug welding requires higher welding tooling, so the pole lug must be pressed firmly to ensure the welding gap. It can realize the high-speed welding of S shape, spiral shape and other complex trajectories, increase the joint area of the weld and strengthen the welding strength.

2. The welding of cylindrical cell is mainly used for the welding of the positive electrode. Because the shell of the negative electrode is thin, it is very easy to weld through. At present, some manufacturers use the negative electrode free welding process, the positive electrode is laser welding.

3. When the square battery combination is welded, the pole or the connecting piece is polluted. When the connecting piece is welded, the pollutants decompose and the welding explosive point is easy to form, resulting in holes; Batteries with thin poles and plastic or ceramic components are easy to weld through. When the pole is small, it is easy to weld to the plastic burning, forming a burst point. Do not use multi-layer connection sheet, there are pores between the layers, not easy to weld.

4. The most important process of the welding process of the square battery is the encapsulation of the shell cover, which is divided into the welding of the top cover and the bottom cover according to the different positions. Some battery manufacturers because of the small volume of the battery production, the use of the "deep drawing" process to make the battery shell, only the top cover welding. The welding methods of square battery are mainly divided into side welding and top welding. The main advantage of side welding is that it has less influence on the inside of the cell, and the splash will not easily enter the inside of the shell cover. Because the welding may lead to a bulge, which will have a slight impact on the assembly of the subsequent process, so the side welding process has high requirements on the stability of the laser and the cleanliness of the material. As the top welding process is welded on the same surface, it has low requirements for the integration of welding equipment and simple mass production, but it also has two disadvantages. One is that there may be a little splash into the cell during welding, and the other is that the front part of the shell has high processing requirements, which will lead to cost problems.

High efficiency and precision laser welding can greatly improve the safety and service life of automotive power battery, and will bring revolutionary progress for the future of automotive power technology; The laser welding parts of the power battery are many, and there are pressure resistance and night leakage test requirements. Most of the materials are aluminum, because the welding is difficult and the welding process has higher requirements. The welding of power battery shell is mainly side welding and top welding, and there are advantages and disadvantages between the two sides. Because of the particularity of its material, the aluminum shell battery is prone to problems such as bulge and porosity, and the square battery welding is prone to problems at the corner.

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top