Lithium-ion battery is currently recognized as the best power battery solution, and is an important component of new energy vehicles. Dynamic force lithium battery is mainly used in electric vehicles, electric bicycles, mobility scooters, also known as lithium-ion power battery, power lithium battery, etc., the main form is divided into cylinder, square and soft pack battery. Because the driving distance of new energy vehicles, top speed, battery vehicle weight ratio, energy density and other technical indicators are closely related to the power battery, the quality of lithium battery directly determines the performance of new energy vehicles, therefore, the power battery is the "heart" of new energy vehicles, the purchase cost of power battery generally accounts for 30%-40% of the entire cost of new energy vehicles; Power lithium battery is mainly ternary material battery and lithium iron phosphate battery, downstream for the installation of new energy vehicle application.

Power battery energy density and safety performance, production automation requirements gradually increased, the production equipment accuracy, safety and consistency of high requirements. As the core component of the new energy vehicle, the power battery has a complex manufacturing process, and its manufacturing technology and equipment requirements are extremely high. On the one hand, the government raises the threshold of financial subsidies, linking the subsidy standard with the battery energy density, encouraging enterprises to continuously optimize the process, improve energy conversion efficiency, increase energy density, and reduce weight. On the other hand, with the continuous expansion of capacity of power battery manufacturers, reducing production cost has become an important consideration for power battery manufacturers. Through equipment automation, improving production efficiency has become an inevitable choice.

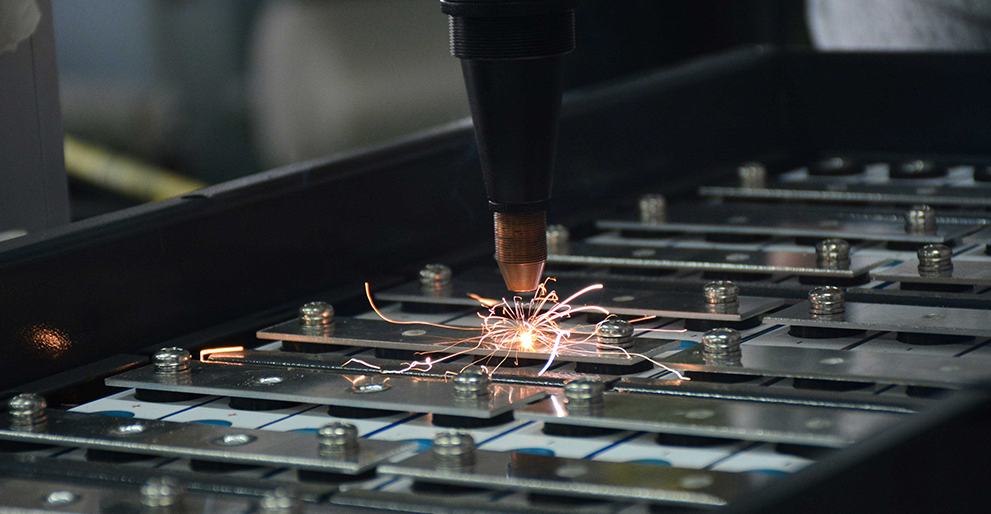

When it comes to automatic production and production efficiency, we have to mention the "Wang fried laser welding machine" of Xinde Laser -- six axis robot laser welding machine and automatic through-type lithium battery laser welding machine.

Six-axis robot laser welding machine, as the name suggests, it has six axes, each axis has a motor equipped with a reducer, and each axis is different in the way and direction of movement, each axis is actually to simulate the action of the various joints of the human hand. The biggest feature of the six-axis robot is that it can weld 360°, and multiple stations can be welded simultaneously within the effective range of the arm span, which greatly increases the output of the battery.

Automatic through-line lithium battery laser welding machine, for some mass production of lithium battery manufacturers, is really not too good to use. It has a flow type automatic production line, which can automatically transport products to the welding area. After automatic identification by the visual positioning system, the battery PACK welding can be completed accurately and quickly in one time. It is a professional highly intelligent laser welding equipment for automatic lithium battery pack production line.

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top