New energy PACK whole line solution provider

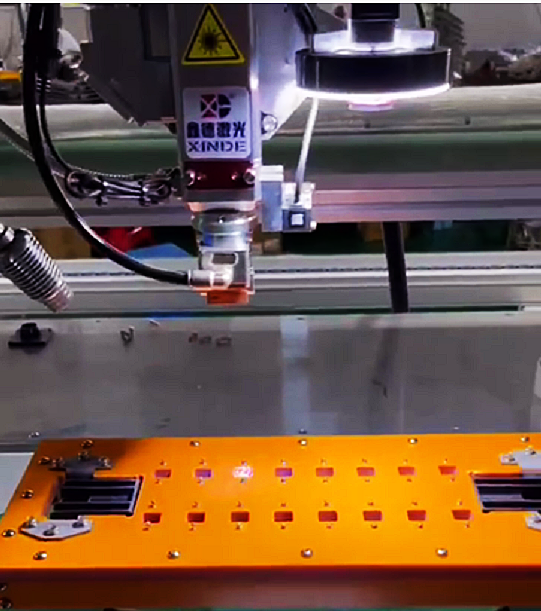

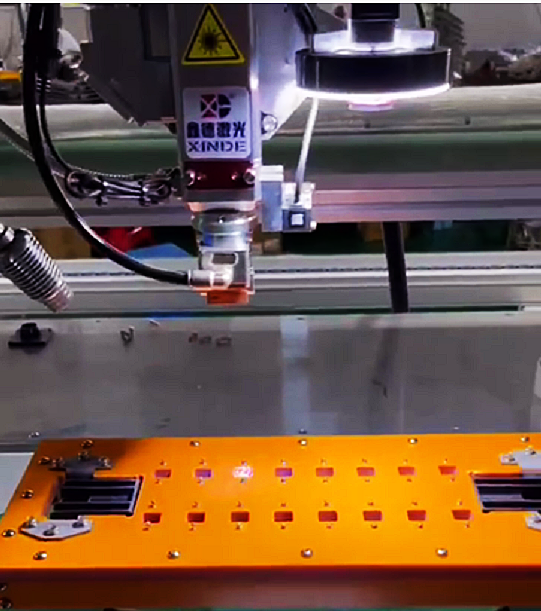

What is laser welding? Laser welding process specification

What is laser welding? Laser welding is a new type of welding, mainly for thin-wall materials, precision parts welding, spot welding, butt welding, stack welding, sealing welding, etc., high depth to width ratio, small weld width, small thermal effect, small deformation, fast welding speed, smooth and beautiful welding, no processing after welding or only simple processing, high welding quality, no porosity, accurate control, small spot spot, High positioning accuracy, easy to realize automation. It is because of so many advantages of laser welding that laser welding plays an important role in the application of laser material processing technology.

The welding process belongs to the heat conduction type, that is, the laser radiation heats the workpiece surface, and the surface heat diffuses internally through the heat conduction. By controlling the width, energy, peak power and repetition frequency of the laser pulse and other parameters, the workpiece is melted to form a specific molten pool. Because of its unique advantages, it has been successfully applied in the welding of micro and small parts. The appearance of high power CO2 and YAG laser opens up a new field of laser welding. The deep bonding based on the theory of keyhole effect is obtained, which has been widely used in machinery, automobile, steel and other industrial sectors.

Compared with other welding technology, the main advantages of laser welding are: laser welding speed, large depth, small deformation. It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, a laser passes through an electromagnetic field and does not deflect the beam; The laser can be welded in air and a certain gas environment, and can be welded through glass or transparent beam materials.

After laser focusing, the power density is high, in the welding of high power devices, the depth to width ratio can be up to 5:1, up to 10:1. It can weld refractory materials such as titanium, quartz, etc., and can weld heterosexual materials with good results. For example, when copper and tantalum, two very different materials, are welded together, the pass rate is almost 100 percent. Micro welding is also available. The laser beam can obtain a small spot after focusing, and can be precisely positioned, can be applied in the mass automatic production of micro, small components welding, for example, integrated circuit lead, watch gosset, picture tube electron gun assembly, etc. due to the use of laser welding, not only the production efficiency is large, high, and the heat affected zone is small, welding spot pollution-free, greatly improve the quality of welding.

The role of laser welding:

It can weld the parts that are difficult to access, and implement non - contact distance welding, with great flexibility. Optical fiber transmission technology is used in YAG laser technology, so that laser welding technology has been widely popularized and applied. The laser beam is easy to realize beam splitting according to time and space, and can carry out multi-beam processing and multi-station processing at the same time, which provides conditions for more precise welding.

Compared with other welding technology, the main advantages of laser welding are: laser welding speed, large depth, small deformation. It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, a laser passes through an electromagnetic field and does not deflect the beam; The laser can be welded in air and a certain gas environment, and can be welded through glass or transparent beam materials.

After laser focusing, the power density is high, in the welding of high power devices, the depth to width ratio can be up to 5:1, up to 10:1. It can weld refractory materials such as titanium, quartz, etc., and can weld heterosexual materials with good results. For example, when copper and tantalum, two very different materials, are welded together, the pass rate is almost 100 percent. Micro welding is also available. The laser beam can obtain a small spot after focusing, and can be precisely positioned, can be applied in the mass automatic production of micro, small components welding, for example, integrated circuit lead, watch gosset, picture tube electron gun assembly, etc. due to the use of laser welding, not only the production efficiency is large, high, and the heat affected zone is small, welding spot pollution-free, greatly improve the quality of welding.

The role of laser welding:

It can weld the parts that are difficult to access, and implement non - contact distance welding, with great flexibility. Optical fiber transmission technology is used in YAG laser technology, so that laser welding technology has been widely popularized and applied. The laser beam is easy to realize beam splitting according to time and space, and can carry out multi-beam processing and multi-station processing at the same time, which provides conditions for more precise welding.

Recommended reading

- 2023-06-01Square shell lithium battery module pack production line: ideal choice for achieving efficient production and high-quality products

- 2023-01-02Why is automatic laser welding machine so popular

2022-12-29Definition and function characteristics of lithium battery automation pipeline

2022-12-29Definition and function characteristics of lithium battery automation pipeline 2022-12-27Welding manipulator will lead the future of welding automation

2022-12-27Welding manipulator will lead the future of welding automation 2022-12-24What factors are related to laser welding quality

2022-12-24What factors are related to laser welding quality

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top